Build Smarter with Pre-Engineered Buildings (PEBs)

Introduction: A New Era in Industrial Construction

In the evolving world of construction, the demand for faster, cost-effective, and sustainable solutions has never been higher. This is where Pre-Engineered Buildings (PEBs) are transforming industrial construction. With precision engineering, rapid deployment, and long-term durability, PEBs are replacing traditional building methods in sectors like manufacturing, logistics, warehousing, and infrastructure.

What Are Pre-Engineered Buildings (PEBs)?

Pre-Engineered Buildings are steel structures designed and manufactured in factories using pre-determined standards and assembled on-site. Unlike conventional construction, PEBs ensure greater quality control, reduced waste, and much faster project completion.

Learn more about PEB systems from American Institute of Steel Construction (AISC).

Top Benefits of Pre-Engineered Buildings

1. Faster Construction Time

PEBs can reduce project timelines by up to 50%. Components are manufactured off-site and quickly assembled on-site, enabling rapid project delivery.

See a real-world case study by Zamil Steel.

2. Cost-Efficient Industrial Building Solution

With lower material waste, fewer labor requirements, and streamlined logistics, PEBs offer a more affordable alternative to conventional buildings. They’re ideal for startups and established industries alike.

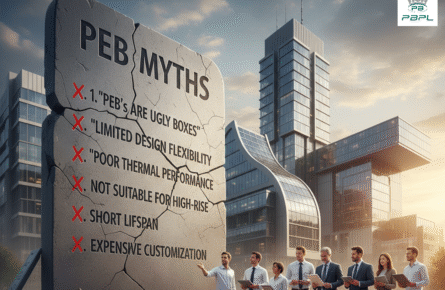

3. Flexibility in Design

Contrary to old stereotypes, modern PEBs allow high levels of architectural freedom. From mezzanine floors to complex facade systems, these buildings can be adapted for virtually any industrial need.

4. Structural Strength & Durability

PEBs are built using high-tensile, corrosion-resistant steel, which ensures longevity even in tough environmental conditions. They are also designed to withstand seismic and wind loads.

Refer to Bureau of Indian Standards IS 800 for steel structure design guidelines.

5. Eco-Friendly Construction

Steel is 100% recyclable. Plus, with less on-site pollution and minimal waste, PEBs are environmentally sustainable—ideal for green-certified industrial projects.

Explore sustainable construction practices from the World Green Building Council.

Applications of PEB in Industrial Construction

PEBs are widely used in:

-

Warehouses and storage units

-

Manufacturing facilities

-

Logistics hubs

-

Cold storage buildings

-

Power plant structures

- Aviation hangars and vehicle workshops

These buildings offer scalability, flexibility, and quick return on investment—making them ideal for rapidly growing businesses.

Why Industrial Developers Are Choosing PEBs

-

Reduced lead time

-

Lower cost per square foot

-

Expandable modular design

-

Compliance with industry standards

-

Minimal maintenance requirements

Compare with traditional construction methods at Construction World.

PEBs vs. Conventional Construction: Quick Comparison

| Feature | Pre-Engineered Buildings | Traditional Construction |

|---|---|---|

| Speed | 6–10 weeks | 6–12 months |

| Cost | Up to 30% less | Higher due to labor and materials |

| Flexibility | Modular & expandable | Limited |

| Sustainability | High | Moderate to low |

| Maintenance | Minimal | Higher long-term cost |

Conclusion: Build Smarter, Build Faster

Pre-Engineered Building solutions are revolutionizing the way industrial spaces are designed and constructed. They offer an unbeatable combination of speed, savings, and structural integrity.

Whether you’re building a factory, logistics hub, or warehouse, switching to PEBs could be the smartest move for your business.

Let’s Build Your Next Project with PEB

Looking for reliable PEB suppliers or manufacturers?

Contact Panjetani Buildwell today for tailored solutions in industrial steel structures, prefab panels, and turnkey construction.